Là một nhà sản xuất, bạn biết rằng độ chính xác là tối quan trọng. Từ nguyên liệu thô đến thành phẩm, mọi phép đo đều quan trọng. Khi nói đến việc cân các vật phẩm lớn, nặng, một cân sàn đáng tin cậy là một công cụ không thể thiếu. Nhưng một câu hỏi chúng ta thường nghe là: "Cân sàn thực sự chính xác đến mức nào?"

Câu trả lời đơn giản là: nó phụ thuộc. Độ chính xác của cân sàn không phải là một con số cố định duy nhất. Đó là sự kết hợp giữa thiết kế của cân, các thành phần của nó và cách nó được sử dụng và bảo trì. Hiểu được những yếu tố này là chìa khóa để đưa ra quyết định mua hàng sáng suốt và đảm bảo hoạt động của bạn diễn ra suôn sẻ và hiệu quả.

Các Yếu Tố Chính Quyết Định Độ Chính Xác của Cân Sàn

1. Cấp và Độ Phân Giải của Cân

Trong thế giới cân công nghiệp, độ chính xác thường được xác định bởi một lớp NIST (Viện Tiêu chuẩn và Công nghệ Quốc gia) hoặc OIML (Tổ chức Đo lường Pháp định Quốc tế). Các lớp này phân loại cân dựa trên hiệu suất của chúng đối với các ứng dụng hợp pháp.

Lớp II (Độ chính xác cao): Thường được sử dụng cho các ứng dụng phòng thí nghiệm hoặc cân rất chính xác.

Lớp III (Độ chính xác trung bình): Đây là lớp phổ biến nhất cho cân sàn công nghiệp, phù hợp với nhiều ứng dụng từ vận chuyển và tiếp nhận đến sản xuất chung.

Lớp III L (Độ chính xác thấp hơn): Được sử dụng cho các cân có tải trọng lớn nhưng độ phân giải thấp hơn, như cân xe tải.

Cảm biến phân giải của cân đề cập đến đơn vị đo lường nhỏ nhất mà nó có thể hiển thị. Một cân có độ phân giải cao hơn có thể phát hiện những thay đổi nhỏ hơn về trọng lượng, nhưng điều quan trọng là phải khớp độ phân giải với nhu cầu cụ thể của bạn. Ví dụ, một cân có độ phân giải 1 lb (0,45 kg) thường đủ để cân pallet, trong khi có thể cần độ phân giải cao hơn để kiểm soát chất lượng.

2. Cảm biến tải và Chất lượng của chúng

Cảm biến tải là trái tim của một chiếc cân kỹ thuật số. Nó là một bộ chuyển đổi chuyển đổi lực của trọng lượng thành tín hiệu điện. Chất lượng và số lượng cảm biến tải ảnh hưởng đáng kể đến độ chính xác và độ bền.

Cân cảm biến tải đơn: Thường được tìm thấy trên các nền tảng nhỏ hơn, chúng dễ bị lỗi tải lệch tâm hơn.

Cân bốn cảm biến tải: Hầu hết các cân sàn công nghiệp đều sử dụng bốn cảm biến tải, một ở mỗi góc. Thiết kế này phân phối tải trọng đều và cung cấp độ chính xác tốt hơn nhiều, đặc biệt là với tải lệch tâm.

Để có hiệu suất tốt nhất, hãy tìm các cân có cảm biến tải kiểu chùm cắt hoặc kiểu hộp mực chất lượng cao được làm từ các vật liệu bền như thép hợp kim hoặc thép không gỉ.

3. Điều kiện môi trường

Ngay cả chiếc cân tốt nhất cũng có thể bị ảnh hưởng bởi môi trường của nó. Các yếu tố như nhiệt độ, độ ẩm và độ rung đều có thể ảnh hưởng đến độ chính xác.

Nhiệt độ: Sự dao động nhiệt độ có thể khiến các cảm biến tải và khung cân giãn nở hoặc co lại, ảnh hưởng đến kết quả đọc.

Độ rung: Rung động liên tục từ máy móc gần đó có thể khiến kết quả đọc của cân dao động.

Độ ẩm và Bụi: Xếp hạng bảo vệ xâm nhập (IP) là rất quan trọng ở đây. Một cân được xếp hạng IP65 hoặc IP67 là một lựa chọn tốt cho môi trường rửa hoặc điều kiện nhiều bụi, bảo vệ các thành phần bên trong khỏi bị hư hại.

4. Lắp đặt và hiệu chuẩn thích hợp

Một chiếc cân sàn chỉ tốt khi nó được thiết lập. Việc lắp đặt thích hợp trên một bề mặt bằng phẳng, chắc chắn là điều cần thiết. Sàn không bằng phẳng có thể tạo ra ứng suất trên khung và dẫn đến kết quả đọc không chính xác.

Hiệu chuẩn thường xuyên là thực hành quan trọng nhất để duy trì độ chính xác. Hiệu chuẩn là quá trình điều chỉnh cân để đảm bảo nó đo trọng lượng chính xác so với một tiêu chuẩn đã biết. Chúng tôi khuyên bạn nên hiệu chuẩn thường xuyên ít nhất mỗi năm một lần hoặc thường xuyên hơn tùy thuộc vào mức sử dụng và tiêu chuẩn ngành của bạn.

Cách chọn Cân Sàn Chính Xác cho Nhu Cầu của Bạn

Là một nhà sản xuất Trung Quốc, chúng tôi hiểu sự cân bằng giữa chất lượng và chi phí. Đây là những gì chúng tôi khuyên các đối tác quốc tế của chúng tôi nên xem xét:

Xác định độ chính xác bạn yêu cầu: Sai số chấp nhận được tối đa cho ứng dụng của bạn là bao nhiêu?

Phù hợp với dung lượng với nhu cầu của bạn: Không bao giờ sử dụng cân ở rìa của dung lượng của nó. Một chiếc cân có dung lượng 10.000 lbs (4.536 kg) có thể chính xác đến 1 lb (0,45 kg), nhưng không nên cân các vật phẩm chính xác 10.000 lbs trên đó.

Kiểm tra chứng nhận: Tìm kiếm các chứng nhận NTEP (đối với Hoa Kỳ) hoặc OIML (đối với Châu Âu và Châu Á), đảm bảo cân đáp ứng các tiêu chuẩn hiệu suất cụ thể.

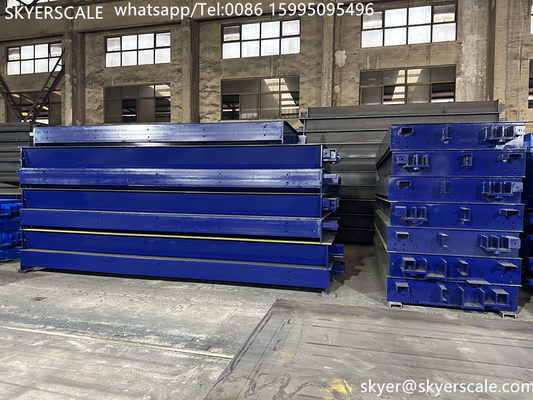

Xem xét vật liệu: Đối với môi trường ẩm ướt hoặc ăn mòn, hãy chọn một cân sàn bằng thép không gỉ. Đối với các ứng dụng khô, mục đích chung, một chiếc cân bằng thép carbon bền là một lựa chọn tiết kiệm chi phí.

Hỏi về dịch vụ và hỗ trợ: Hợp tác với một nhà sản xuất cung cấp dịch vụ hậu mãi mạnh mẽ, bao gồm hỗ trợ kỹ thuật và phụ tùng.